In the ever-growing construction and home improvement industry, the demand for high-quality, durable, and energy-efficient windows has never been higher.

As a result, businesses in the window manufacturing sector must rely on cutting-edge technology to meet these needs.

One such essential piece of equipment is the uPVC window making machine, which plays a crucial role in the production of uPVC (unplasticized poly vinyl chloride) windows.

This machine not only improves the quality of windows but also boosts production efficiency, helping businesses stay competitive.

In this article, we will dive into the importance of UPVC windows, the features of a UPVC window making machine, and the benefits it brings to manufacturers and consumers alike.

The aim of this article is to provide a comprehensive and in – depth exploration of UPVC window making machines.

By delving into the characteristics, advantages, and applications of these machines, we hope to equip readers, especially those in the construction, manufacturing, or business – related fields, with the knowledge necessary to make informed decisions.

Whether you are a professional looking to invest in new manufacturing equipment, a builder considering the best window – making options for your projects, or an entrepreneur interested in entering the uPVC window production market, this article will serve as a valuable resource.

We will cover everything from the basic components and working principles of uPVC window making machines to the latest technological advancements, market trends, and tips on choosing the right machine for your specific needs.

What is the uPVC?

Before exploring the uPVC window making machine, it’s important to understand the material used in these windows.

uPVC is a strong, durable, and low-maintenance plastic used in the manufacturing of windows and doors.

Unlike regular PVC, uPVC does not contain plasticizers, making it more rigid and durable.

Its excellent resistance to weathering, corrosion, and decay makes it ideal for use in windows and doors.

Additionally, uPVC windows are energy-efficient, providing better insulation and reducing energy costs for homeowners.

We also call uPVC window making machine vinyl window making machine.

What is uPVC Window Making Machine?

1. Definition

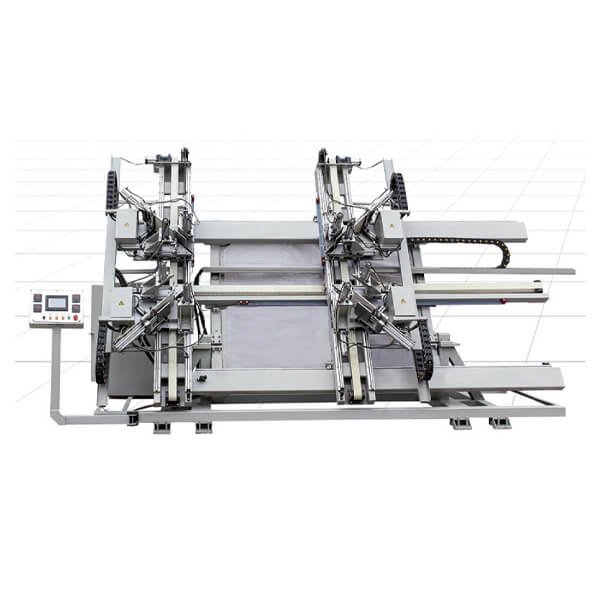

A uPVC window making machine is designed to automate and streamline the production process of uPVC windows and doors.

2. What it does in the window production line

This machine is equipped with various components that handle different stages of window manufacturing, from cutting and shaping profiles to welding, corner cleaning, and assembling the final window.

By automating these processes, manufacturers can significantly increase production capacity and ensure that each window meets the highest quality standards.

3. Who needs it

Normal Types of uPVC Window Making Machine

According to the main functions of the Aluminum Window Making Machine, we can category several normal types of aluminum window making machine.

Please check them as follows:

1. uPVC Window Cutting Machine

The first step in making a uPVC window is cutting the uPVC profiles into the correct lengths.

The uPVC window making machine is equipped with a profile cutting saw that can make precise, clean cuts.

uPVC window cutting machine is an very import machine in the uPVC window manufacturing equipment.

uPVC profile cutting machine is mainly used to cut, shape, or modify uPVC window door profile extrusions with high precision.

These machines come in various forms, such as single head, double head, 3 axis, 5 axis, CNC and manual.

Each type of the uPVC window production machinery is tailored to specific applications, offering unique advantages in terms of speed, accuracy, and cost-efficiency.

If you want to know more details about the uPVC window cutting machines, please check below:

2. Copy Router Machine / Drilling Milling Machine

To create space for hardware such as hinges, locks, and handles, drilling and milling operations are performed.

The uPVC window making machine includes drilling and milling units that precisely cut holes in the frame, allowing for proper installation of the window’s hardware.

Below are the uPVC window fabrication machines which mainly used for drilling and milling.

3. uPVC Window Corner Welding Machine

Once the profiles are cut to the required size, they need to be joined at the corners to form a complete frame.

A corner welding unit is an essential part of the uPVC window making machine.

This uPVC welding machine uses high-frequency heat to weld the corners of the profiles, creating a strong bond.

This process ensures that the window frame is durable.

Below are some uPVC window processing equipment for welding corners.

Exmplore more about the Complete Guide to uPVC Window Welding Machine

4. uPVC Corner Cleaning Machine

After welding, the corners of the frame are cleaned to remove any excess material or welding residue.

This step is crucial for ensuring that the finished window has a smooth and professional appearance.

The corner cleaning unit of the uPVC window making machine removes any excess material efficiently, ensuring the final product is polished and ready for assembly.

Below is the uPVC window fabrication equipment for uPVC window corner cleaning.

5. uPVC Window Frame Automatic Screwdriver

This uPVC window making machinery is mainly used to fix the reinforcement steel and uPVC profiles.

This uPVC window fasten machine is very useful for the bulk production

Below are some uPVC window assembly machines for screw fasten the reinforcement .

6. uPVC Window Bending Machine

This uPVC bending machine is mainly used to bend the uPVC window door profile.

Then to make the arch window door.

7. All in one smart line uPVC window production line

With technology in the uPVC window making field development, more and more automatic uPVC window manufacturing machines come out.

These robot lines, smart lines, workstations, and relatively intelligent production lines with AI or Chatgpt help us to reduce labor cost, more intelligent, and more automatic.

This window door industry is stepped into Industrial 4.0 in the window fabricating industry.

Benefits of Using a uPVC Window Making Machine

The use of a UPVC window making machine brings numerous benefits to manufacturers and customers alike.

Let’s explore some of the key advantages:

1. Increased Efficiency and Productivity

One of the main advantages of using a uPVC window making machinery is the increased efficiency it brings to the production process.

Automation allows for faster and more consistent production, reducing human error and the need for manual labor.

With a higher production capacity, manufacturers can meet growing demand while keeping costs low.

2. Cost Savings

While investing in a uPVC window fabrication machinery requires an upfront cost, the long-term savings can be substantial.

By automating the production process, manufacturers can reduce labor costs and minimize material waste.

Additionally, the machine’s precision reduces the likelihood of defects and rework, leading to fewer material losses.

3. Improved Product Quality

The uPVC window processing machinery ensures that each window is produced to precise specifications.

From profile cutting to welding and assembly, every step is automated to guarantee consistency and high-quality results.

This level of precision improves the overall appearance and durability of the finished windows, making them more appealing to customers.

4. Customization Options

Modern uPVC window assemebly equipment is designed to handle various customization options, allowing manufacturers to produce windows in different shapes, sizes, and styles.

Whether it’s a casement window, sliding window, or a custom design, the machine can accommodate these variations, making it easier for manufacturers to meet specific customer requirements.

5. Energy Efficiency

uPVC windows are known for their energy-efficient properties.

They provide excellent insulation, helping to keep homes cooler in summer and warmer in winter.

This energy efficiency is a result of the high-quality manufacturing process, which is optimized by the uPVC window fabrication systems machine.

By using a machine that guarantees precise cuts and seamless welding, manufacturers can ensure that their windows are energy-efficient and meet industry standards for insulation.

How to find best uPVC Window Making Machine Supplier Manufacturer

When selecting a uPVC window making machine, there are several factors that manufacturers should consider to ensure they invest in the right equipment for their business:

- Define Your Requirements

• Capacity: Determine the scale of your operation and the production volume you need.

• Machine Features: Identify the specific machines you require (e.g., cutting, milling, crimping).

• Budget: Set a budget for your investment. This will effect use small uPVC window making machine or standard one.

• Location: Decide whether you want a local supplier or are open to importing.

- Research Potential Suppliers

• Online Marketplaces: Browse platforms like Google for a wide range of suppliers.

• Industry Trade Shows: Attend exhibitions focused on uPVC fabrication or window manufacturing to meet suppliers in person.

• Local Distributors: Look for local distributors who may have a network of reputable manufacturers.

- Evaluate uPVC window fabrication equipment suppliers

• Experience: Check how long the uPVC window making machinery suppliers have been in the business.

• Reputation: Read customer reviews and testimonials to assess reliability.

• Portfolio: Examine case studies or examples of their machines in use.

- Assess Machine Quality

• Specifications: Ensure the uPVC window making machine meets your technical requirements.

• Materials Used: High-quality materials and components indicate durability.

• Precision and Performance: Look for machines with accurate and efficient output.

• Technology: Check if the machines use modern technologies like CNC controls.

- Compare Pricing and Warranty

• Price Transparency:

Request detailed quotes, including shipping, installation, and training costs.

Please note that uPVC window making machine price is not the only one factor to consider.

If uPVC window making machine price has very large difference please make sure you are talking the same machine.

Please always remember an important rule do not think you pay less and get more.

• Warranty Terms:

Favor suppliers that offer a comprehensive warranty and after-sales service.

- Check After-Sales Support

• Training and Installation: Verify if the supplier provides training for your staff.

• Maintenance Services: Ask about the availability of spare parts and technical support.

• Customer Service: Test their responsiveness and willingness to assist.

- Request Samples or Factory Visits

• Samples: If possible, request sample machines or test runs.

• Factory Visits: Visiting the supplier’s factory can give insights into their production capabilities and quality standards.

For machines normally samples not suitable, but factory visit it will be better.

Is it good to buy used uPVC window making machine?

Buying a second-hand uPVC Window Making Machine can be a cost-effective decision, but it comes with potential risks.

Here’s a breakdown of the pros and cons, along with tips to help you make an informed decision for used uPVC window machine.

Limited Warranty: Most used machines don’t come with a warranty, so repairs and maintenance costs may fall on you.

Unknown Maintenance History: Wear and tear or improper use by the previous owner could lead to frequent breakdowns.

Obsolete Technology: Older machines may lack advanced features or compatibility with modern software.

Higher Repair Costs: Replacing worn-out parts on older machines can be expensive or difficult if parts are no longer available.

Buying a second-hand machine is a good option if:

1- Your budget is limited.

2- The machine is in good condition and meets your needs.

3- You’ve professional and know well about the machines.

However, if your production process requires high precision, minimal downtime, or the latest technology, investing in a new machine may be a better choice in the long term.

Best uPVC Window Making Machine Brand Manufacturer and supplier

Several reputable companies specialize in manufacturing UPVC window making machines, providing a range of equipment to suit different production needs.

Here are some notable top brands:

- Yilimaz uPVC window fabrication machinery

- Haffner uPVC window processing equipment

- Fenstek uPVC window manufacturing machine

- Moxisys uPVC window making machine

- OZGENC uPVC window manufacturing equipment

uPVC Window Making Machine Price Guide

- Price range in India / China / Other regions

- Factors affecting price

- New vs. Used machine cost

- OEM/ODM customization pricing

People Also Ask (FAQs)

A uPVC window making machine is specialized equipment designed to automate the production of UPVC (unplasticized poly vinyl chloride) windows.

It handles various stages of manufacturing, including cutting, welding, corner cleaning, drilling, and assembling window frames.

This automation enhances production efficiency and ensures consistent quality.

The main components include:

• Profile Cutting Unit: Cuts UPVC profiles to precise lengths.

• Corner Welding Unit: Joins profiles at corners using heat to create strong bonds.

• Corner Cleaning Unit: Removes excess material and smooths welded corners.

• Drilling and Milling Unit: Creates holes for hardware installation.

By automating critical manufacturing processes, the machine reduces manual labor, minimizes errors, and speeds up production.

This leads to higher output and consistent product quality.

• Cost Savings: Automation reduces labor costs and material waste.

• Improved Quality: Precise manufacturing ensures high-quality windows.

• Customization: Machines can produce windows in various styles and sizes to meet diverse customer needs.

• Energy Efficiency: UPVC windows offer excellent insulation, contributing to energy savings.

• Production Capacity: Select a machine that aligns with your production volume requirements.

• Automation Level: Higher automation can lead to greater efficiency but may require a larger investment.

• Customization Options: Ensure the machine can handle the specific window designs you plan to produce.

• After-Sales Support: Reliable technical support and availability of spare parts are crucial for machine maintenance.

The machine ensures precise cutting and welding, resulting in windows with better insulation properties.

High-quality UPVC windows reduce heat loss in winter and keep interiors cooler in summer, leading to lower energy consumption.

Yes, operators should:

• Wear Protective Gear: Use appropriate safety equipment, such as gloves and eye protection.

• Follow Operating Procedures: Adhere to the manufacturer's guidelines for safe operation.

• Regular Training: Ensure all operators are trained in machine safety protocols.

Implementing a quality control system that includes:

• Regular Inspections: Check dimensions and functionality of windows during production.

• Testing: Conduct tests for strength, insulation, and other relevant properties.

• Feedback Loop: Use customer feedback to identify and address quality issues.

Why Choose Our UPVC Window Making Machine

- Company introduction (1 paragraph)

- OEM & Customization support

- Global delivery & support

- Customer success case

Conclusion

The uPVC window making machine is an essential tool for modern window manufacturers looking to produce high-quality, durable, and energy-efficient windows.

With automation, precision, and efficiency at the forefront, these machines offer numerous benefits, including increased productivity, cost savings, and improved product quality.

By investing in a uPVC window making machine, businesses can stay ahead of the competition and meet the growing demand for high-performance windows in the construction and home improvement industries.

If you want to know little about “how uPVC windows are made” please check it.

Explore more about the upvc window making process, please check below:

uPVC Window Making: The Definitive Guide

And we also have an article for Top 10 uPVC Window Manufacturing Machines for New factories.

Need a step-by-step setup guide? Read our complete uPVC manufacturing plant setup guide.

Planning your finances and ROI? See our full business plan with equipment list.

If you want to find a best uPVC window making machine for sale, and get a good uPVC window making machine price.

Please contact us by below form.