In modern window and door manufacturing, aluminium window cutting equipment forms the backbone of fabrication.

The accuracy, speed, and versatility of a cutting machine determine the final quality of every frame produced.

For fabricators and factory owners looking to enhance production, understanding the available machines, their configurations, and their cost-benefit analysis is essential.

What is Aluminium Window Cutting Equipment?

Aluminium window cutting equipment refers to a range of machines designed to precisely cut aluminium profiles used in window and door frames.

These machines ensure accurate dimensions and perfect joint angles, contributing to smooth assembly and long-term durability.

Types include:

- Manual Cutting Machines

- Semi-Automatic Cutting Machines

- Fully Automatic CNC Cutting Centers

- Double Head Mitre Saw Machines

Types of Aluminium Cutting Machines for Window Production

1. Manual Mitre Saw

Best for startups or custom, low-volume projects. It requires human handling and skill.

2. Semi-Automatic Cutting Machine

Controlled movement with pneumatic clamps and hydraulic saw blade feed. Good for medium-size production.

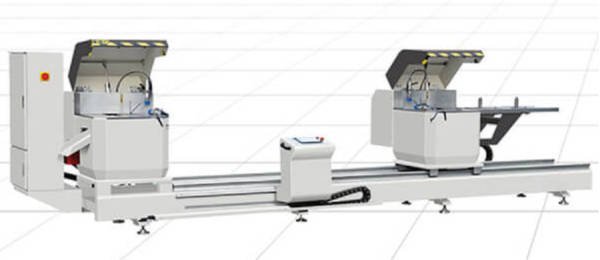

3. Double Head Aluminium Cutting Machine

Dual-blade system with synchronized cuts, widely used for accurate cutting of large window frames.

4. CNC Aluminium Cutting Center

High-end machine for automated profile positioning, measurement, and precision cutting.

5. Angle-Cutting Saws

Used for special angle profiles and arch or curtain wall applications.

Features to Consider When Choosing a Cutting Machine

Blade Diameter and Speed: Determines depth and smoothness of the cut

Cutting Length & Angles: Adjustable angles for complex frames

Cooling & Lubrication: Extends blade life

Digital Controls: Better accuracy and consistency

Clamping System: Secure profile positioning during cuts

Aluminium Window Cutting Process: Step-by-Step

Profile Measurement: Profiles are marked based on frame design

Feeding the Profile: Manual or automated loading to the machine

Adjusting Angle: Set the blade angle for mitre or square cuts

Cutting: Machine executes the cut

Deburring: Smooth the edges before assembly

Price Overview of Aluminium Cutting Machines (USD, 2025)

| Machine Type | Price Range (USD) |

|---|---|

| Manual Mitre Saw | $650 – $1,200 |

| Semi-Automatic Cutter | $1,500 – $3,000 |

| Double Head Cutting Machine | $3,500 – $7,500 |

| CNC Cutting Center | $12,000 – $25,000 |

Benefits of Using Quality Aluminium Cutting Equipment

High Accuracy: Maintains tight tolerances and clean finishes

Faster Production: More frames cut per hour

Reduced Waste: Fewer off-cuts with optimized nesting

Consistency: Uniform size improves assembly and fitting

Long-Term Savings: Lower maintenance and fewer defects

Common Brands in the Market

Some common brands for aluminium window cutting equipment as below:

FOM (Italy)

URBAN (Germany)

Moxisys (China) – OEM customization experts

Yilmaz (Turkey)

Kaiue Machine (China) – Growing brand

Haffner (Germany)

Tips for Maintaining Aluminium Cutting Machines

Below are some tips for maintain aluminium window cutting equipment:

Clean blade area daily to avoid profile chips accumulation

Sharpen or replace saw blades regularly

Check alignment settings weekly

Lubricate moving parts according to schedule

Train operators to handle machine properly

Final Thoughts

Choosing the right aluminium window cutting equipment is a strategic investment for your window and door production business.

Whether you’re running a high-output CNC facility or a custom frame workshop, there are tailored machines to meet your needs.

Optimizing your production with reliable cutting tools not only improves frame quality but also boosts business profitability in the long run.

Explore more about Aluminium Window Making Machine.