The uPVC window welding machine is a core component of any modern window fabrication plant.

It ensures seamless joining of uPVC window profiles with precision, strength, and consistency.

Whether you’re a startup or scaling up your fabrication line, understanding how welding machines work and how to choose the right one is essential.

In this comprehensive guide, we’ll explore types, features, pricing, installation, and the role of welding in the uPVC window fabrication process.

1. What is a uPVC Window Welding Machine?

A uPVC window welding machine is used to join the corners of uPVC profiles by melting the surface and fusing them together.

This forms strong, leak-proof joints essential for structural strength and insulation.

These machines are commonly used in uPVC window and door manufacturing.

2. Types of uPVC Window Welding Machine

a. Manual Welding Machine

- Operated by hand and foot switches

- Lower cost and easy maintenance

- Suitable for low-volume production

b. Semi-Automatic Welding Machine

- Partially automated; requires operator for alignment

- Higher output than manual

- Suitable for small-medium fabricators

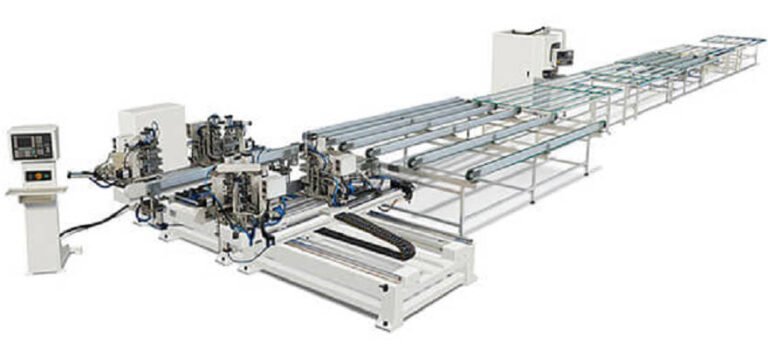

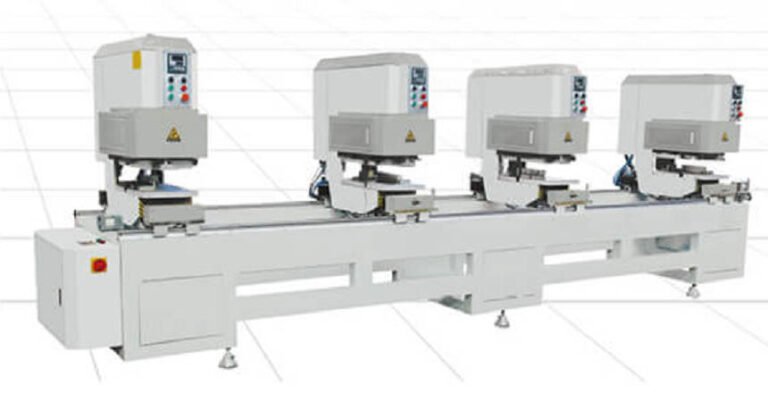

c. Fully Automatic Welding Machine

- High-precision CNC-controlled operation

- Can weld four corners at once

- Includes automatic alignment, pressing, and cooling

- Best for large-scale production

d. Seamless Welding Machine

- Leaves no visible weld seam

- Great for colored or laminated profiles

- Enhances visual appearance and premium quality

3. Key Features to Look For uPVC Window Welding Machine

Welding Precision: Accuracy in angles and flush alignment

Temperature Control: Consistent heating ensures strong bonds

Cycle Time: Faster cycle times mean higher productivity

Multi-head Support: Single, two, or four-head options

Seamless Finish Capability: For high-end profile fabrication

Digital Controls: For temperature, pressure, and timing

Energy Efficiency: Saves electricity in long operations

4. Welding Machine Process in uPVC Fabrication

Profile Preparation: Profiles are cut to size and aligned.

Heating: Machine plates heat the surface.

Joining: The heated profiles are pressed together.

Cooling: Pressure is maintained until the bond sets.

Corner Cleaning: Residue is cleaned with corner cleaner (manual or CNC).

Check more about How UPVC Windows Are Made: Manufacturing Process Explained

Or you can also check the other article: uPVC Window Making: The Definitive Guide

5. Price Comparison of uPVC Welding Machine (2025)

| Type | Price Range (USD) |

|---|---|

| Manual Single Head | $1,500 – $2,500 |

| Semi-Automatic Two Head | $3,800 – $6,500 |

| Fully Automatic Four Head | $11,000 – $18,000 |

| Seamless Welding Machine | $14,000 – $22,000 |

Prices vary based on brand, build quality, digital controls, and add-ons.

6. Top Brands for uPVC Welding Machine

FOM (Italy) – High precision European engineering

URBAN (Germany) – Seamless weld technology

Moxisys (China) – OEM customization experts

Yilmaz (Turkey) – Wide range of affordable options

SAICON (India) – Growing brand with local support

FENSTEK (China) – Seamless and corner welding specialists

Haffner (Germany) – Used by large fabricators worldwide

7. Factory Setup and Layout Tips

Keep welding zone isolated from profile cutting for safety

Install fume extraction systems

Use rubber flooring to prevent static

Allow space for movement of profiles and trolleys

Explore Complete Setup Guide for a UPVC Window Manufacturing Plant

8. Maintenance and Troubleshooting

Below are some points for uPVC Window Welding Machine maintenance:

- Clean heating plates daily

- Regularly check for temperature calibration

- Replace worn-out Teflon coating timely

- Use UPS for control system protection

- Keep spare sensors and air filters in stock

9. Training and Operator Skills

For the uPVC Window Welding Machine, operators must be trained in:

- Temperature and pressure settings

- Emergency shutdowns

- Corner alignment inspection

- Daily cleaning and maintenance

- Well-trained staff reduce defects and rework.

10. Final Thoughts

A uPVC window welding machine is a must-have in any fabrication plant setup.

Choosing the right type — manual, semi-auto, or fully automatic — depends on your scale and budget.

For premium profile fabrication, a seamless welding machine is the ultimate investment.

Investing in the right welding machine improves production quality, efficiency, and customer satisfaction.

Explore more about uPVC Window Making Machine.